Boron Carbide Ceramic Body Armor

Representative examples include sapi shape double curve triple curve.

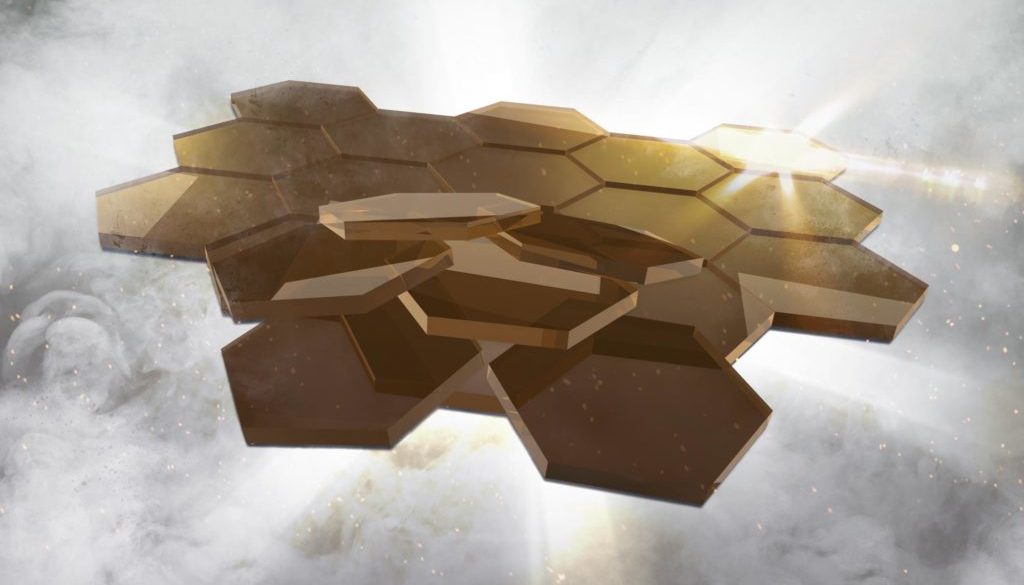

Boron carbide ceramic body armor. This unique combination led to the rapid adoption of boron carbide for high end armor systems allowing them to be lighter and more effective. 4 5x harder than rha steel. Silicon carbide is although much lighter still heavy enough to be burdensome. Boron carbide composites are primarily used for ceramic plates to protect against smaller projectiles and are used in body and helicopters.

The commercially manufactured ceramics for armor include materials such as boron carbide aluminium oxide silicon carbide titanium boride aluminiumnitride and syndite synthetic diamond composite. Alumina is far too heavy to such an extent that even steel armor is now giving it a run for its money. Applications for boron carbide plates have included aircraft armor and elite body armor. The boron carbide are widely used as dense parts sandblasting industrial bulletproof nuclear and so on applications.

With a vickers hardness of 30 gpa it is one of the hardest known materials behind cubic boron nitride and diamond. 44 lighter than titanium. Excellent thermal shock resistance 3. A ideal material for production of body armor bulletproof armors for vehicles ships helicopters and so on.

Lee and yoo 2001 conducted an analysis of a ceramic metal armor system in which the strain rate effect was considered and the ballistic limits for different ceramic metal back plate ratios were derived. Also boron carbide is harder and lighter than other armor materials like silicon carbide making it an ideal choice for protective gear particularly ballistic vests. A dash of silicon improves boron carbide body armor january 23rd 2020 posted by texas a m university credit. Superior chemical inertness 4.

Boron carbide chemical formula approximately b 4 c is an extremely hard boron carbon ceramic and covalent material used in tank armor bulletproof vests engine sabotage powders as well as numerous industrial applications. 2003 performed experiments for the ballistic impact on a boron carbide plate and they found that the loss of impact resistance of boron carbide is due to the phase. Our cerashield reaction bonded boron carbide has low density for ultra lightweight designs. The best grades of boron carbide although nearly 40 lighter than alumina and more than.

Photographer s mate 1st class aaron ansarov us navy via wikimedia commons. Providing advanced ceramic body armor components with high volume manufacturing capabilities to armor integrators developing next generation body protection. With the ever changing technologies out today many soldiers have worn both steel and ceramic body armor plates. Ceramic is an inorganic non metallic material customarily made from nitride or carbide.